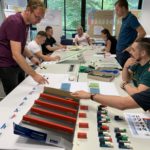

To be able to apply and implement the Lean Management Philosophy, you have to understand it! We accompany and support this process with our Lean Management Workshops. Therefore, we use our standard modules for different target groups from different areas of responsibility and background knowledge or we create workshops based on the clients needs. Committed to the Lean principle “Go to Gemba” (“Go to the place of action”), we recommend to let the workshops take place on spot. In this way, we ensure the immediate transfer of the skills imparted in the workshop into practice.

In addition to these standard modules, we also offer new concepts and workshops that include influences from other sectors and areas of responsibility. Among others, the workshop “FORDEC – quick and correct decisions” as a problem solving or leadership strategy or the workshop “AGILE – agile and efficient project management” as a supplement to the company’s own change and development process. For these workshops, we cooperate with experts and trainers, e.g. from the aviation industry, so we can refer to experience of active trainers.

For example, our FORDEC workshop is conducted together with an active training captain of an airline and includes the application of the learned strategies during a simulator session. The participants of the workshop sit at the controls themselves and are guided and supported by active pilots!

- 1. Simulation

- 2. Schematize

- 3. Teamwork

- 4. Start Production

- 5. Transfer into practice

Possible workshop topics

- Lean Management Basics / Introduction to the Lean Management Philosophy

- Lean Management implementation steps

- Added value and waste incl. on-site analysis

- 5S method, immediate measures to prevent waste

- SFM – Shopfloor Management

- PDCA – Systematic Problem Solving (W.E. Deming)

- FORDEC – Quick and correct decisions

- Value stream mapping and value stream design (manufacturing)

- Process mapping and process design (administration)

- Workplace design based on Lean Management

- SMED – setup time optimisation

- LCA – Low Cost Automation and Karakuri in production

- TPM – Total Productive Maintenance

- OEE – Overall Equipment Effectiveness

- KANBAN – Line Back Principle, logistics concepts

- CIP – Continuous Improvement Process

- AGILE – agile and efficient project management

Comments are closed.