Lean Basic

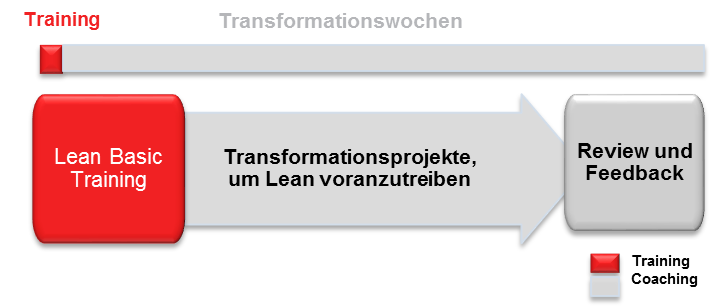

The Lean Basic Training is suitable for all employees in your company – from production staff to controllers – and imparts fundamental knowledge about the Lean Philosophy and how it helps to improve processes within the company. There are no admission requirements, so any employee interested in improving is welcome.

Contents

- Providing fundamental knowledge about the Lean Philosophy

- Origin of Lean production principles

- Importance of added value and waste

- Analysing processes

- Tact, flow and pull

- Importance of standards

- Theoretical and practical contents

Benefits

The Lean Basic Training is the first step in transforming your organisation into a value-added, modern company. Through the participation of employees from all sections, a common understanding of Lean and its importance for the entire organisation will be developed. Each employee will act as a multiplier who supports the Lean implementation in the company.

Lean Practitioner

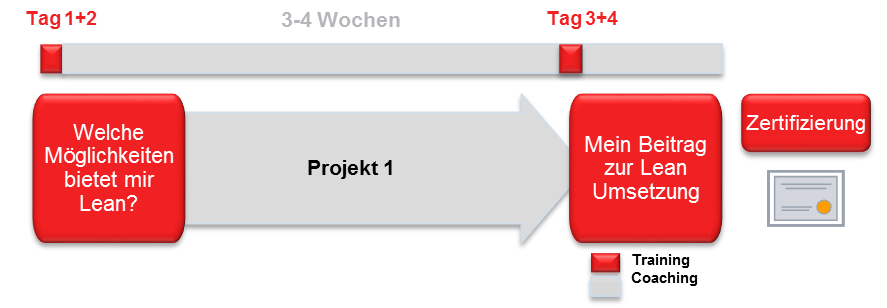

The Lean Practitioner Training is designed to address employees from all production sections like manufacturing, montage, maintenance, as well as administrative sections. In just a few days, group trainings provide an advanced understanding of the Lean Philosophy. Furthermore, the group trainings are supplemented by a practically oriented project in the participant’s field. Thereby, the participants are supported by our Lean coaches.

Contents

- Elaboration of Lean methods and tools

- Defining and establishing standards

- Prevention of waste in the own workspace

- Methodologies in the workspace (5S, SMED. PDCA, etc.)

- Internalisation of the Lean Philosophy

- Transformation project

- Applying the training contents to the own field of activity

- Certification audit to examine the qualitative and quantitative project results

Benefits

Due to the Lean Practitioner Training, your employees will understand the importance of the compliance of standards in their everyday work and they will actively help to identify and eliminate waste. In addition, the training serves to strengthen the company’s learning and improvement culture and thus supports the continuous improvement process as well as the Lean transformation.

Lean Expert

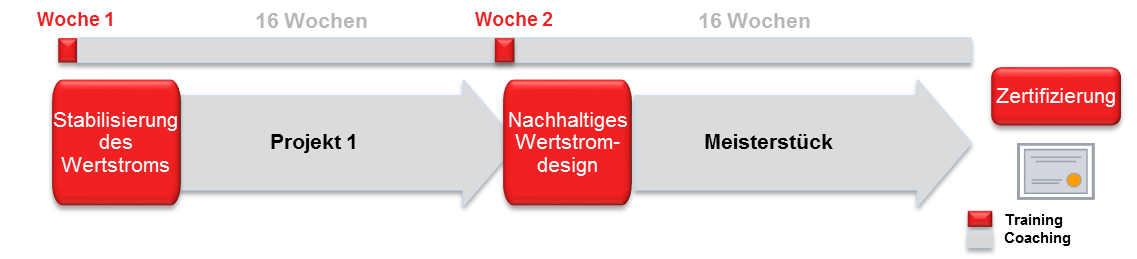

For employees of production and support sections we offer the Lean Expert Training. For a successful participation, knowledge on Lean Practitioner level, first project management experience as well as moderation and presentation skills are required. In several group trainings, a deeper understanding of Lean methods and tools is imparted, which is complemented by an individual, practically oriented transformation project as well as a masterpiece project. During the project, participants are supported by experienced Lean coaches. Furthermore, all projects are challenging the participants and focused on achieving productivity goals.

Contents

- Deeper understanding of Lean methods and tools

- The role of a Lean Expert

- Recognising and eliminating waste

- Value stream mapping and value stream design

- Capacity calculation based on customer contact

- Systematic problem solution

- Applying the contents to practical problems in one’s own field of activity

- Transformation project

- Masterpiece

Benefits

The Lean Expert Training empowers your employees to identify and eliminate waste in all processes continuously. They will be able to improve the flow in flexible manufacturing cells and lines. Moreover, they will be able to accompany other employees on their way to a lean production in order to create a sustainable improvement process.

Comments are closed.